THUMPONATOR

A fishing thumper to attract Whites, Hybrids, and Stripers

THUMPONATOR's now come with Wi-FI that enables control from your smartphone! (tempo/pause/resume)

|

|

|

Always $200 (Plus tax and $15 shipping)

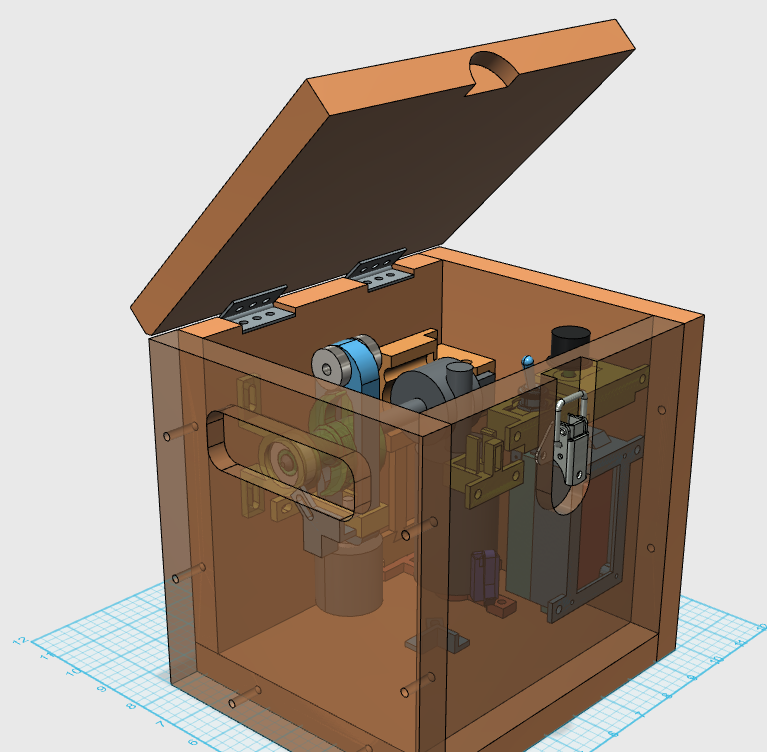

Making of the THUMPONATOR

See how its made and whats inside

4/11 WI-FI for Smartphone control

|

My goal was to create an affordable and reliable fishing thumper. (less than $200).

I will be using my 3d printer to create custom parts that I can easily assembled into a finished product with minimal effort.

Several bearings will be used to reduce any friction and noise other than the dropping lead (thump instead of thump-clank-thump).

I will run a 100hr test to see what if any noticable wear and tear there is on the PLA plastic being used.

After several months, most of the design work is done, now comes the printing and assembly and refinement of tolerances. |

THUMPONATOR Design

|

|

|